List of Materials for this Project:

Pine pieces:

2 pcs 70mm x 45mm x 770mm (the main uprights)

2 pcs 70mm x 45mm x 340mm (the feet)

1 pce 70mm x 45mm x 600mm (main bridge piece)

2 pcs Pine rails/dowels 40mm diameter x 600mm

Plywood pieces:

2 pcs 45mm x 22mm x 318mm (Rail supports)

1 pce 70mm x 15mm x 600mm (Guitar neck holder)

1 pce 55mm x 15mm x 600mm

8 pcs 12mm dia. dowels 50mm long 4 pcs 8mm dia. dowels 40mm long

4 x 45mm screws ( For fixing the rails)

2 pcs Black soft leather 140mm x 600mm

5 pcs Black leather 15mm x 95mm.

Glue used for the wood and leather was waterproof PVA.

Please note. Watch the Youtube build video to better understand this tutorial.

STEP 1:

Round the ends of the feet(340mm) and both uprights(770mm). In the build video I used a piece of 120mm pvc pipe to mark the 60mm radius on one end of all four pieces (Fig.1). The easiest way to create nice smooth identical curves is using a disc sander making sure that the table is set square to the sanding disk (Fig.1a & Fig.1b).

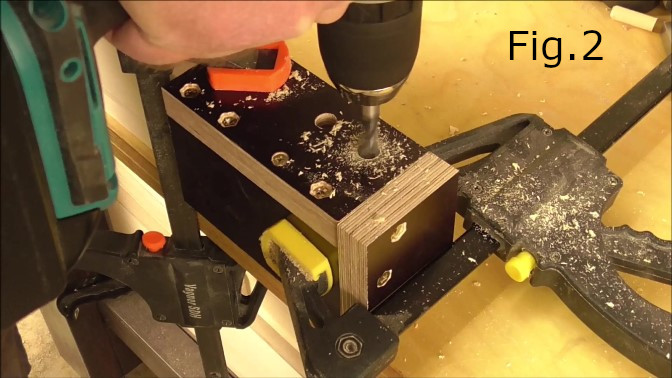

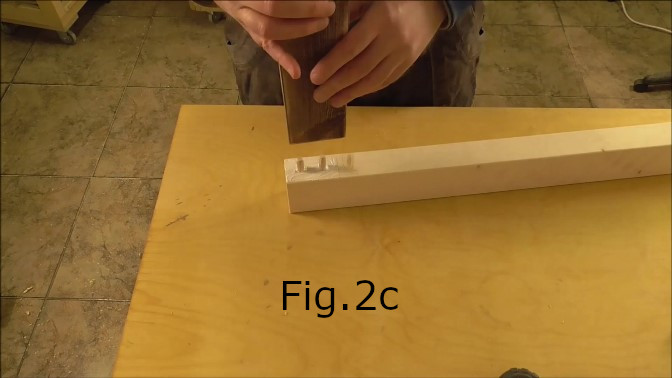

STEP 2:

Next drill the holes for the 12mm x 50mm dowels in the uprights and feet. I made a simple dowel drilling jig to make sure I drilled the holes straight and vertical(see project video). You don’t have to use a drilling jig you can drill the first holes in the uprights(Fig.2b) using a drill press, mark the dowels with a marker and transfer the corresponding hole locations to the feet. Same method as seen in Fig.5a, Fig.5b & Fig.5c. Make sure to drill the holes a little bit deeper than half the length of the dowels to provide space for the glue in each hole and make sure you can press the pieces together tight. Also make sure to not drill the holes too close to the edges of each piece. Once the holes are drilled, glue the uprights and feet together. Make sure when clamping together that the feet are square to the uprights and straight(Fig.2d).

STEP 3:

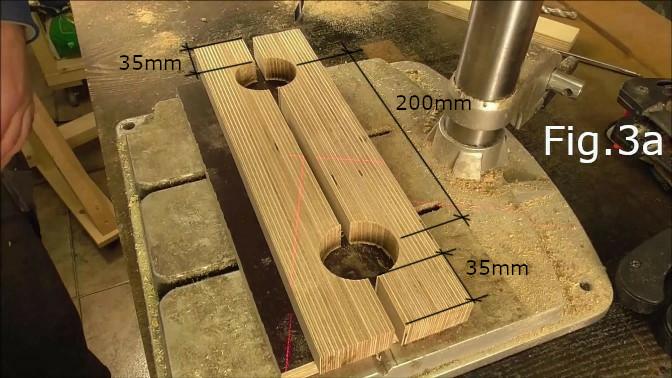

Take both of the 318mm long plywood rail support pieces. Clamp them together side by side as in Fig.3. Next mark along the join line two center points 200mm apart for drilling both the 44mm diameter holes with a hole saw(Fig.3). These holes form the supports for the rails/dowels(Fig.3a). The 200mm distance between holes may not be ideal for all guitars. Some guitars have their guitar lead sockets or metal strap lugs in different places so check your guitars and if needed increase or decrease the distance between the holes for the rails/dowels and modify the other dimensions accordingly.

STEP 4:

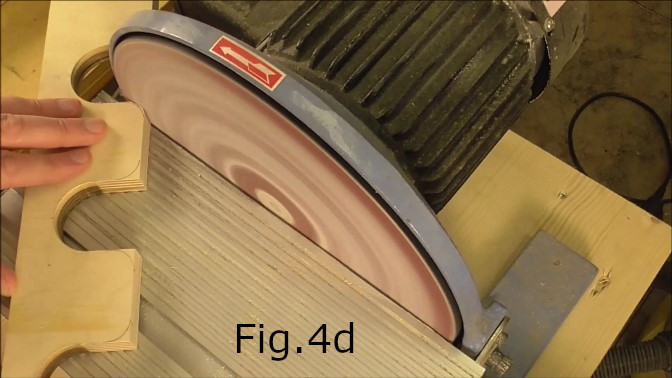

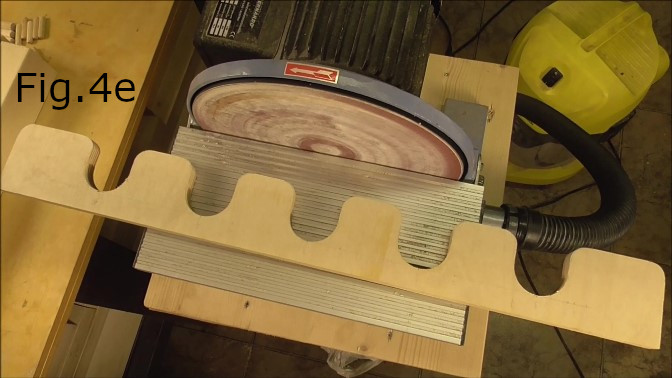

Drill five equally spaced holes using the 44mm hole saw(Fig.4 & Fig.4a) in the 70mm x 15mm x 600mm (Guitar neck holder) piece. The holes are 100mm between centers and the first and last holes are 100mm from the ends(Fig.4b). Draw a line along the length of the piece 40mm from rear edge(Fig.4) and along this line mark the centers for drilling. Next cut the holes open on the front side of the piece with a jigsaw or hand saw(Fig.4c). Using a disc or belt sander round the corners. The radius on the corners is approximately 10mm(Fig.4d).

STEP 5:

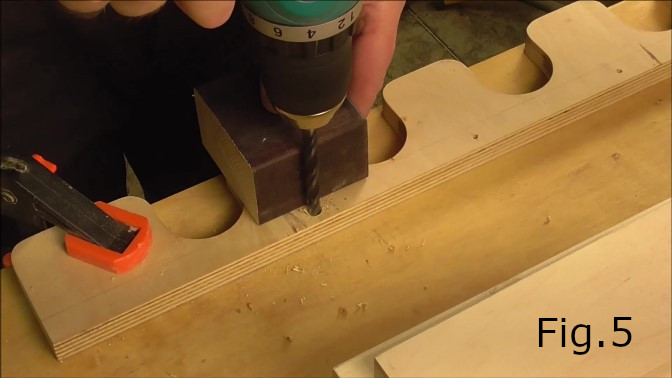

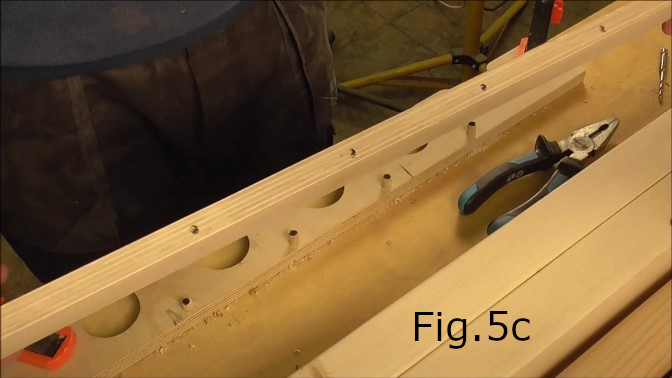

In the same neck holder piece, drill four holes 100mm between centers for the 8mm diameter dowels which connect this piece of plywood with the 55mm x 15mm x 600mm plywood piece(Fig.5). Drill the holes between the recesses for the guitar necks created in the previous step. Use a drill press or a square piece of wood to ensure the drill stays at 90 degrees to the work(Fig.5). Mark or tape the drill bit or use a depth stop on your drill press so as not to drill the holes too deep. After drilling the four holes, Transfer the drilling hole locations for the 55mm x 15mm x 600mm plywood by marking some shortened dowels(Fig.5a,Fig.5b & Fig.5c) and align both pieces and press together. Next drill the four corresponding holes in the edge of the 55mm plywood piece(Fig.5d). Place the piece either in a vise or clamp it between two pieces of wood as shown in Fig.5d. Glue both the pieces together and clamp, making sure both pieces stay square at 90 degrees to each other(Fig.5e & Fig.5f).

STEP 6:

Take the 70mm x 45mm x 600mm (main bridge piece) and drill two holes in each end for the 12mm diameter dowels(Fig.6 & Fig.6a). I used the dowel jigs to drill these holes but, you can use the method shown in Fig.5c to mark and drill the dowel holes with correct alignment. Once you have transferred the hole locations to the uprights you can drill the corresponding holes(Fig.9).

STEP 7:

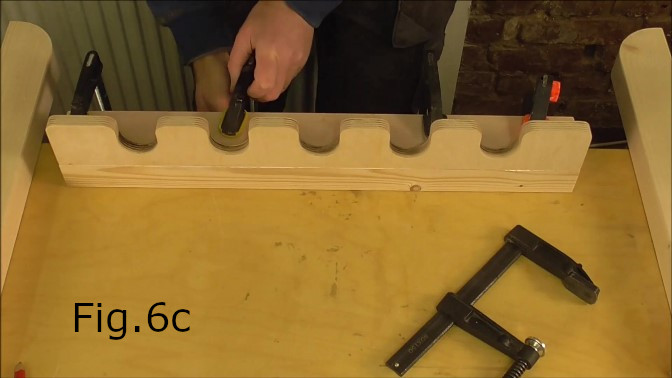

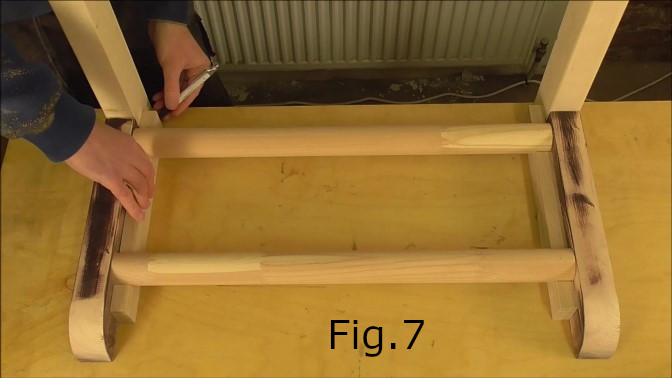

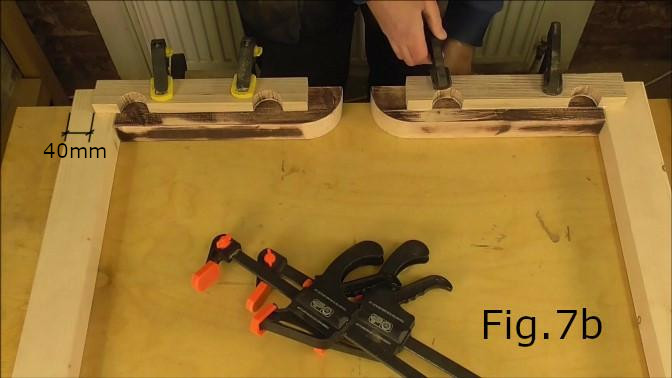

Glue the plywood neck holder to the main pine bridge piece(Fig.6b). Spread the glue out evenly and clamp the two pieces together once you have them aligned(Fig.6c). Next take the plywood Rail/dowel supports that were drilled in Fig.3a and position them on the inside of the feet with the rails/dowels in place so you can mark the correct position for gluing the rail supports(Fig.7). The ends of both the rail supports should be 40mm in from the rear outside edge of the uprights(Fig.7b). Once you have marked the positions glue the rail supports in place(Fig.7a & Fig.7b).

STEP 8:

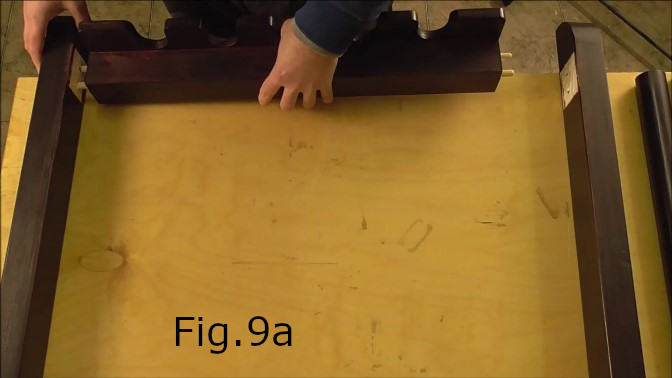

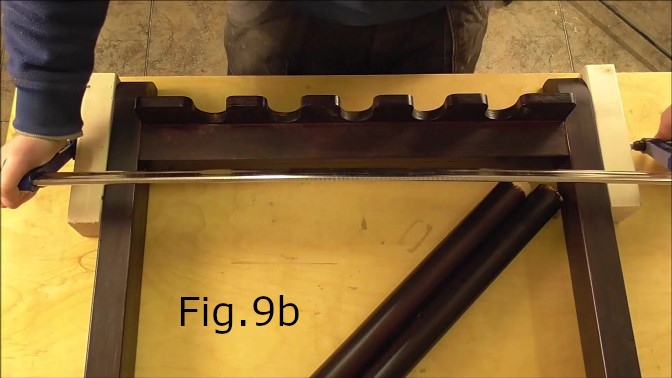

Apply a wood stain or paint the stand depending on what your preference may be. I applied multiple coats of a wax based wood stain. My method is not the traditional or correct way to apply a stain but I wanted a dark finish so I applied multiple coats and waited several days for the stain to completely dry(Fig.8). In Fig.9a you can see I left bare patches where the neck holder needs to be glued in place. It’s important during the gluing process to make sure you minimize the glue squeeze out and remove any glue outside the joints by sanding or scraping. Most stains will not soak into wood that has glue on it. Next mark the dowel holes for the neck holder/bridge piece in the uprights and drill the holes(Fig.9). I used drilling jigs for this but you can use the method in Fig.5c or use your own drilling jigs. Use four of the 12mm x 50mm dowels, glue and clamp in place(Fig.9a & 9b). In Fig.8 you can see the dowels have been stained. I replaced these with unstained dowels as it is better to glue leather to unstained wood.

STEP 9:

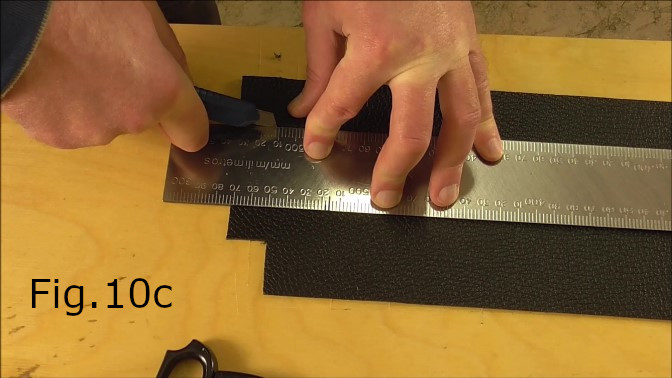

If you have not already done so, cut the leather pieces for the neck holders and pine dowels. The leather pieces for the neck holders are 15mm x 95mm. In Fig.10 you can see I used a piece of 15mm plywood as a cutting guide for the neck holder pieces. The leather pieces for the dowels need to be first cut to 600mm x 140mm and then cut to fit around the dowels and dowel supports (Fig.10b,10c & 10d).

STEP 10:

Attach the pine dowels to the feet of the stand. Hold the dowels in place and drill a hole through the center of the plywood rail supports and through the middle of the dowel at least halfway into the dowel itself(Fig.11 & Fig.11a). Drill four holes, one for each end of the pine dowels to accommodate a 45mm screw. Countersink the holes. Screw in the screws so the screw heads are flush with the bottom surface(Fig.11b).

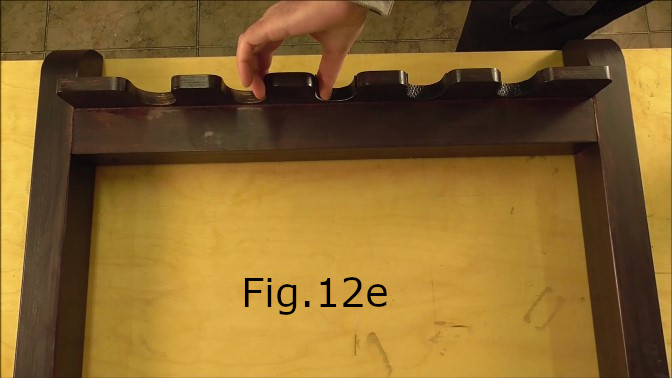

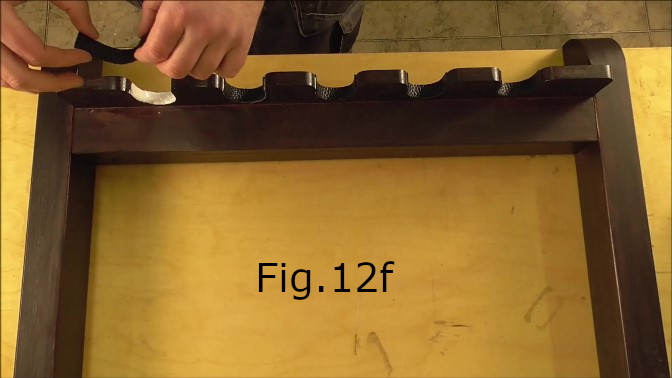

STEP 11:

Glue all the leather pieces to the stand. For gluing the leather I used the same standard waterproof PVA wood glue as used for gluing the wooden joints. Make sure when gluing the large leather pieces to the dowels that you don’t stretch the leather when applying it. If you are using soft leather it is easy to stretch it. If you cut it accurately it will cover all of the dowel. Also make sure to apply the glue evenly(Fig.12) so you avoid glue lumps under the leather. Once you apply the leather(Fig.12a) if you apply pressure with your hands the leather should stick fairly quickly and wrap around the wooden dowels(Fig.12b & 12c). I stained the neck holders so before I glued on the leather pieces I lightly sanded where the leather would be applied(Fig.12d). Again by using light hand pressure the leather pieces stay in place and quite quickly stick to the wood(Fig.12e). Make sure each of the leather pieces are placed in the center of each neck holder. Wipe off any excess glue. Once the glue for the leather pieces has dried the guitar stand is finished.